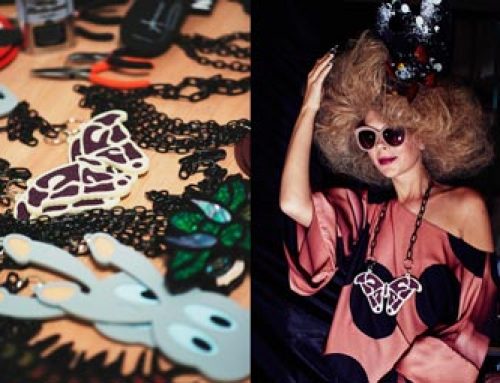

Laser cut prototype

When our customer came to us with a 3d printing job (and a student’s budget!) this week we had to look into alternatives, on looking closer at his file and the purpose of the model, the obvious answer was a contoured laser cut wood mdf model which could be filled and sanded afterwards.

His CAD file took minutes to break down into cutting layers and a few hours to cut with our CO2 laser. Using dowel holes that we programmed to be cut through the model, the layers were quick to assemble very accurately. The model was glued and handed over to our customer for filling and sanding as requested, at a slither of the cost.

3D printing can be used very effectively with engineering projects and product prototyping where accuracy is essential but the more traditional methods appear to be more frequently not considered and sometimes just as effective if not a better choice. The method of producing this air duct can be likened to low resolution 3d printing as our customer correctly pointed out, building up layers of material as you can see from the image below…

We certainly are advocates of 3d printing, it has some fantastic applications and so much of our work relies on this level of accuracy and detail. But we would never be without our laser cutter!